Microstructural and Mechanical Characterization of WAAM-fabricated Inconel 625: Heat Treatment Effects

DOI:

https://doi.org/10.5545/sv-jme.2024.986Keywords:

Wire Arc Additive Manufacturing (WAAM), Heat treatment, Optical microscope, tensile strengthAbstract

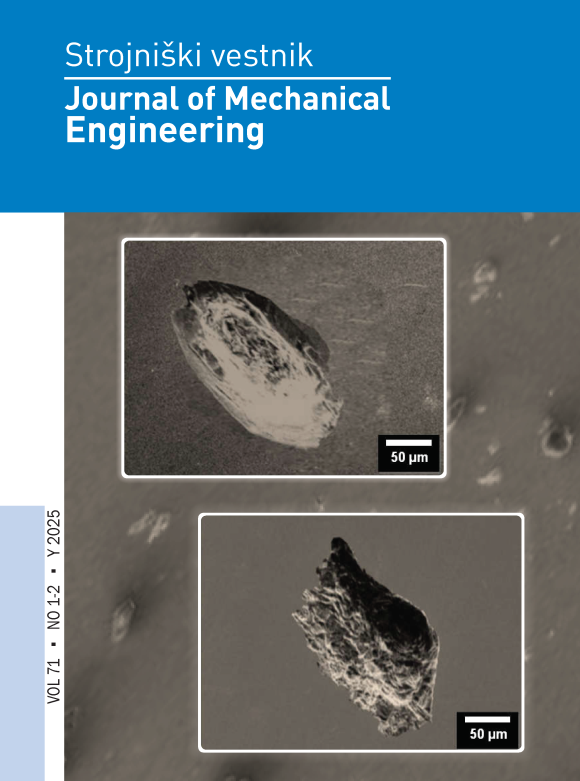

Wire arc additive manufacturing (WAAM) is a promising technique for producing complex geometries of nickel-based superalloys, such as Inconel 625. In this work, the microstructure and mechanical properties of Inconel 625 alloy produced by gas tungsten arc welding (GTAW) process of WAAM technology were analyzed to investigate the effects of heat treatment on the top and bottom zones of the multi-layered wall structure. The deposited specimens were heat treated at 980 °C for 2 hours, then water quenched (solution annealing). After heat treatment, microstructure reveals that the most common phases like laves, gamma, and mono carbides (MC) are dissolved, which is clear by optical microscopy (OM), scanning electron microscopy (SEM), and energy dispersive spectroscopy (EDS). Even after the heat treatment process, mechanical properties, such as micro-hardness results, demonstrate that the bottom zone of the multilayer wall structure has a higher hardness value than the top zone. After the secondary phases were eliminated by the solution annealing procedure, the ultimate tensile strength and yield strength were increased by nearly 17 % to 38 % and 15 % to 22 % in the top and bottom one of the multilayer wall structures, respectively.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 The Authors

This work is licensed under a Creative Commons Attribution 4.0 International License.